INDUCED DRAFT HEAT EXCHANGERS

INDUCED DRAFT

DESIGN

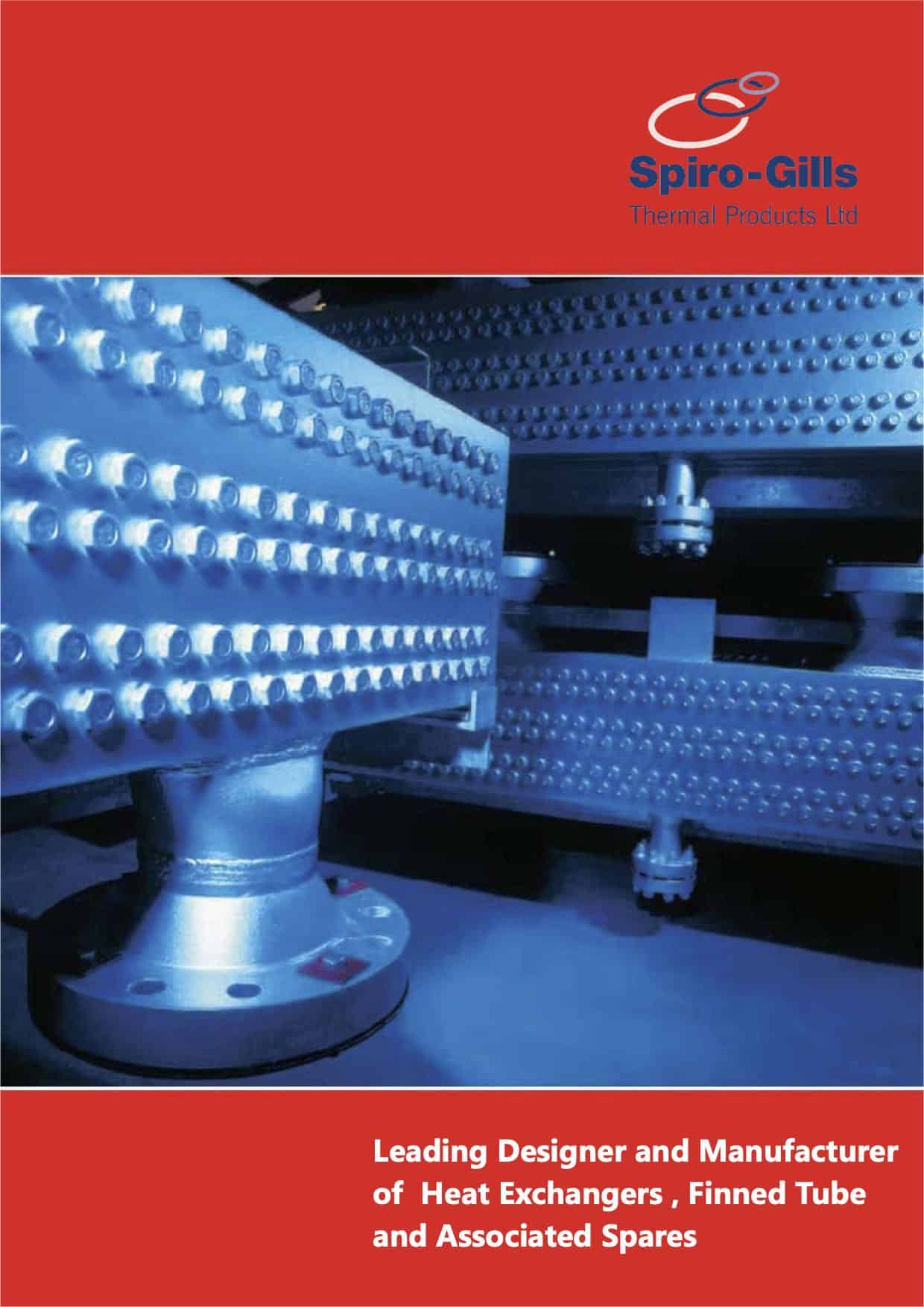

Spiro Gills have a long history of heat exchanger manufacturing and design. We use the latest CNC equipment and HTRI design software to develop cutting edge cooling equipment. Some reasons to used a forced draft cooler are as follows;

Even Cooling Distribution Over Tubed Bundle

Stack Effect Delivers Inherent Cooling

Highly Controllable For Precise Cooling

Superior Protection From The Elements

Reduced Noise When Using Silencers

Induced draft air cooled heat exchangers pull air from below a fin tube bundle, through and around the fins then past the fan blades, exhausting above the unit.

In this design the fans are mounted above the fin tube bundle. The drive motor may be mounted above the fans where the cooling requirement is low and exhaust air will be relatively cool. In most cases the motors and drivetrain are mounted below the tube bundle. This limits the motors exposure to exhaust air exiting the top of the ACHE.

This increased exposure to hot exhaust air increases the maintenance requirement in comparison to forced draft heat exchangers. This addition wear is seen on drive gear, pulleys, fan blades, bearings and mounts where the motor is mounted underneath the finned tube bundle. It would be unusual to mount the motor above the fans in this style cooler but the additional heat would, in theory, reduce the operational life of a motor when mounted above the tube bundle.

Due to the added complexity of induced draft style coolers they are more expensive to produce per (BTU/Watt) of cooling power when compared with forced draft designs. This additional cost is incurred in manufacturing the additional structure required to accommodate weight above the fin tube in the form of fans, plenums, fan rings and drive gear. There is also an additional cost in designing and manufacturing space in the finned tube bundle for drive shafts and additional engineering work for motor mounts and powertrains below the tube bundle.

Although the cost per unit of cooling power is more when compared with forced drafted heat exchangers there are many benefits to the induced draft design. Induced draft heat exchangers are best suited for applications where there is a close approach of product outlet temperature to ambient air temperature. As air is pulled through the ACHE air velocity approaching the bundle is relatively low, this allows air to spread more evenly across the entire surface area of the finned bundle. Forced draft designs show a more concentrated cooling effect on finned tube directly in the air flow path above the fans.

In this design the fans are mounted above the fin tube bundle. The drive motor may be mounted above the fans where the cooling requirement is low and exhaust air will be relatively cool. In most cases the motors and drivetrain are mounted below the tube bundle. This limits the motors exposure to exhaust air exiting the top of the ACHE.

This increased exposure to hot exhaust air increases the maintenance requirement in comparison to forced draft heat exchangers. This addition wear is seen on drive gear, pulleys, fan blades, bearings and mounts where the motor is mounted underneath the finned tube bundle. It would be unusual to mount the motor above the fans in this style cooler but the additional heat would, in theory, reduce the operational life of a motor when mounted above the tube bundle.

Due to the added complexity of induced draft style coolers they are more expensive to produce per (BTU/Watt) of cooling power when compared with forced draft designs. This additional cost is incurred in manufacturing the additional structure required to accommodate weight above the fin tube in the form of fans, plenums, fan rings and drive gear. There is also an additional cost in designing and manufacturing space in the finned tube bundle for drive shafts and additional engineering work for motor mounts and powertrains below the tube bundle.

Although the cost per unit of cooling power is more when compared with forced drafted heat exchangers there are many benefits to the induced draft design. Induced draft heat exchangers are best suited for applications where there is a close approach of product outlet temperature to ambient air temperature. As air is pulled through the ACHE air velocity approaching the bundle is relatively low, this allows air to spread more evenly across the entire surface area of the finned bundle. Forced draft designs show a more concentrated cooling effect on finned tube directly in the air flow path above the fans.

Induced draft ACHE are also less likely to recirculate hot exhaust air due to exit air velocity being much higher when compared with forced draft designs. The covered design of these units display higher heat transfer effects without the fans operating in comparison to forced draft units because of natural convection due to the stack effect.

The primary reason for choosing the induced design over the forced method of cooling is for additional control in unpredictable climates. Increased coverage of air flow across the tube bundle coupled with limited exposure above the bundle to the elements create additional cooling control. Induced draft heat exchangers also benefit from a longer service life in most cases due to this added protection from the weather.

Once you have determined the input, outlet and maximum ambient temperature for your application it is critical to allocate a space in your process or site for your cooler. We have experience working with unusual mounting spaces and locations. Based on the fluid or gas that needs to be cooled, the cooling energy required and the space available we can create a quote to meet your needs.

Our air cooled heat exchanger business is vertically integrated. We quote and design completely in house using HTRI and modern CAD tools. We fin our tube from raw materials for use in our tube bundles. We source, test and prepare all materials for headers and the units structure in house. Spiro Gills has recently invested in two large CNC machines to manufacture increase workshop efficiency. We can manufacture to all products ASME in steel and stainless steel. We have the ability to manufacture finned tube from stainless steel and fin in aluminium, copper or other alloys on request.

The primary reason for choosing the induced design over the forced method of cooling is for additional control in unpredictable climates. Increased coverage of air flow across the tube bundle coupled with limited exposure above the bundle to the elements create additional cooling control. Induced draft heat exchangers also benefit from a longer service life in most cases due to this added protection from the weather.

Once you have determined the input, outlet and maximum ambient temperature for your application it is critical to allocate a space in your process or site for your cooler. We have experience working with unusual mounting spaces and locations. Based on the fluid or gas that needs to be cooled, the cooling energy required and the space available we can create a quote to meet your needs.

Our air cooled heat exchanger business is vertically integrated. We quote and design completely in house using HTRI and modern CAD tools. We fin our tube from raw materials for use in our tube bundles. We source, test and prepare all materials for headers and the units structure in house. Spiro Gills has recently invested in two large CNC machines to manufacture increase workshop efficiency. We can manufacture to all products ASME in steel and stainless steel. We have the ability to manufacture finned tube from stainless steel and fin in aluminium, copper or other alloys on request.

Spiro Gills are pleased to provide you with the following services;

- Thermal design

- Mechanical design of headers and steel structure

- Noise level predictions

- Preparation of the specification sheet

- Preparation of the general outline drawings

- Preparation of proposals

- Price estimation

CONTACT FORM

If you would like more information on any of the services we offer or have any queries then please do not hesitate to contact us.

CONTACT INFO

Stafford

Spiro-Gills Thermal Products Ltd

St Albans Road

Stafford

ST16 3DR

England

St Albans Road

Stafford

ST16 3DR

England