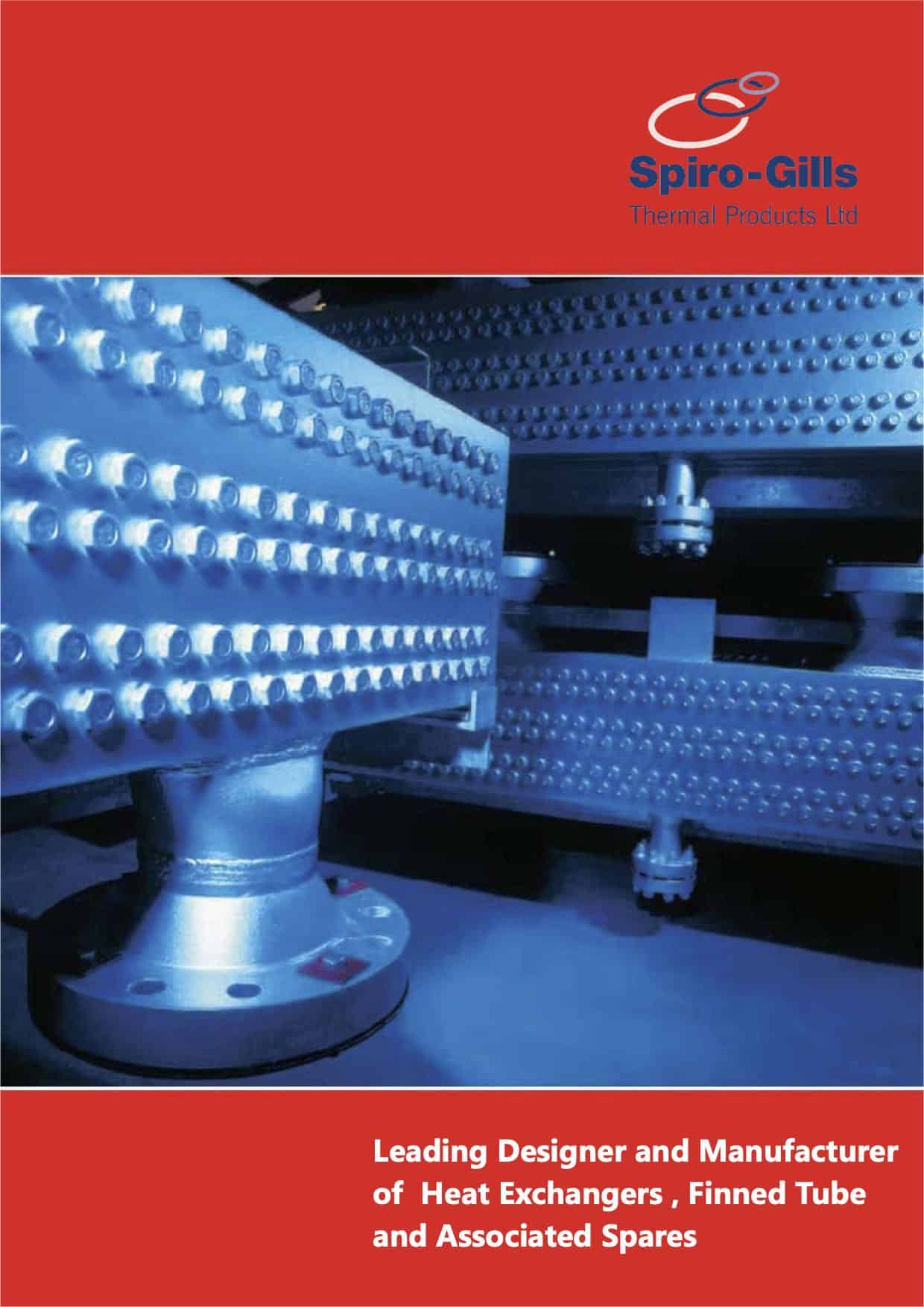

Air Cooled Heat Exchangers

COST

EFFECTIVE COOLING

FOR ANY ENVIRONMENT

Air cooled heat exchangers provide reliable cooling to liquids and gases in hot and dry climates where cooling water is limited. We design each unit to perform based on the worst potential ambient temperature and always provide the correct outlet temperature.

BUILDING

A

FORCED

DRAFT

HEAT

EXCHANGER

FORCED DRAFT AIR COOLED HEAT EXCHANGER

Forced draft fin fan coolers push air from the the bottom of the unit, underneath the tube bundle, through the finned tube and out of the top. Forced draft coolers provide excellent cooling efficiency at a reduced cost in comparison with induced draft coolers.

find out more

INDUCED DRAFT AIR COOLED HEAT EXCHANGER

Induced draft coolers pull air from the bottom of the cooler through the tube bundle and out of the top. This design provides excellent temperature control and more even cooling around the entire surface area of the tube bundle. In addition to this it also protects the finned tube from the elements. The downside of these advantages is a higher operating and manufacturing cost.

Find out moreSpiro-Gills Thermal Products Ltd: Air Coolers and Heat Exchangers for use in oil refineries, petrochemical plants, power generating stations, and fertilizer and gas production plants throughout the world.

Spiro-Gills’ over 70 years experience in the design and manufacture of air coolers and heat exchangers means that our highly trained and experienced thermal design engineers are able to offer a bespoke solution to our customers in the design of their induced draft air coolers or forced draft air coolers and heat exchangers, both thermally and mechanically.

Spiro-Gills Thermal Products Ltd makes use of leading-edge computer equipment, including the latest Computer Aided Design systems, to ensure maximum efficiency in:

Spiro-Gills’ over 70 years experience in the design and manufacture of air coolers and heat exchangers means that our highly trained and experienced thermal design engineers are able to offer a bespoke solution to our customers in the design of their induced draft air coolers or forced draft air coolers and heat exchangers, both thermally and mechanically.

Spiro-Gills Thermal Products Ltd makes use of leading-edge computer equipment, including the latest Computer Aided Design systems, to ensure maximum efficiency in:

- Thermal design

- Mechanical design of headers and steel structure

- Noise level predictions

- Preparation of the specification sheet

- Preparation of the general outline drawings

- Preparation of proposals

- Price estimation

ACHE Design Considerations

PLUG HEADER

The plug header is the most commonly used header type for working pressures up to 350 bar in heat exchangers and air coolers. The plughole opposite each tube allows the finned tube to be expanded into the tube sheet. It also facilitates mechanical cleaning and plugging in case of leakage repairs, re-tubing and upgrading.

For hydrogen service at high pressure, seal welding or strength welding can be provided. This is less expensive than using pipe headers, which are generally employed with a service pressure above 200 bar.

For hydrogen service at high pressure, seal welding or strength welding can be provided. This is less expensive than using pipe headers, which are generally employed with a service pressure above 200 bar.

COVER PLATE HEADER

The cover plate header is used for fluids with high fouling factors up to 40 bar maximum where frequent mechanical cleaning is needed. It is also used for highly corrosive process fluids to allow periodic checking of the corrosion allowance.

For full specifications please download our brochure

For full specifications please download our brochure

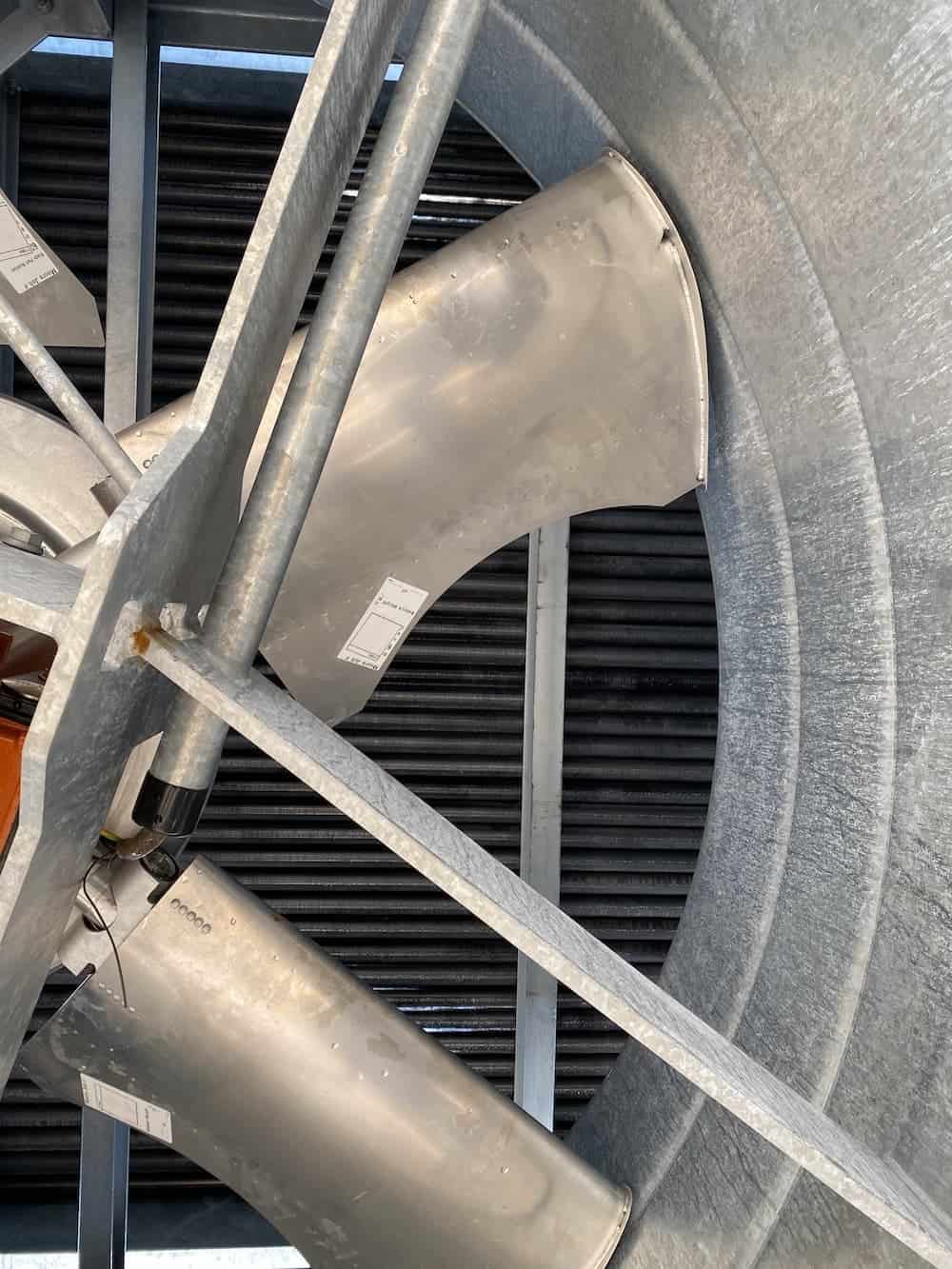

Fan blades

Variable frequency motors have done away, for the most part, with variable pitch fan blades. Each application is different and for this reason the choosing the correct fan blade is critical. Spiro Gills uses the latest HTRI software to determine the correct blade design for every cooler.

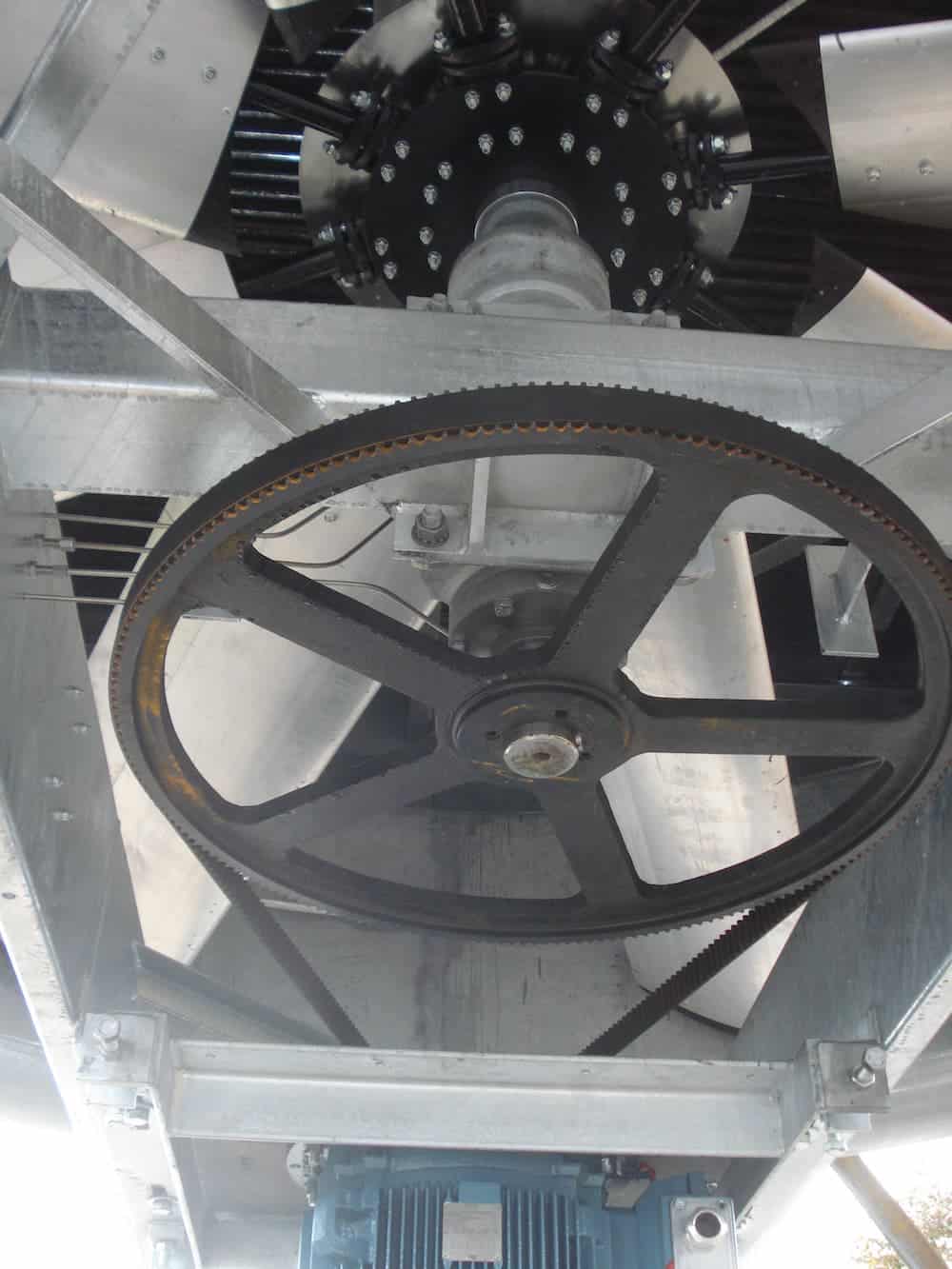

Belt and pulley

Belt and pulley transmissions are used for up to 37kW. Pulleys are dynamically balanced. Belt types are:

• V belt

• Toothed belt (HTD)

• ChevronBelts

Gear drives

Gear drives are generally preferred for over 37kW and are:

• Parallel shaft

• Right-angle drive

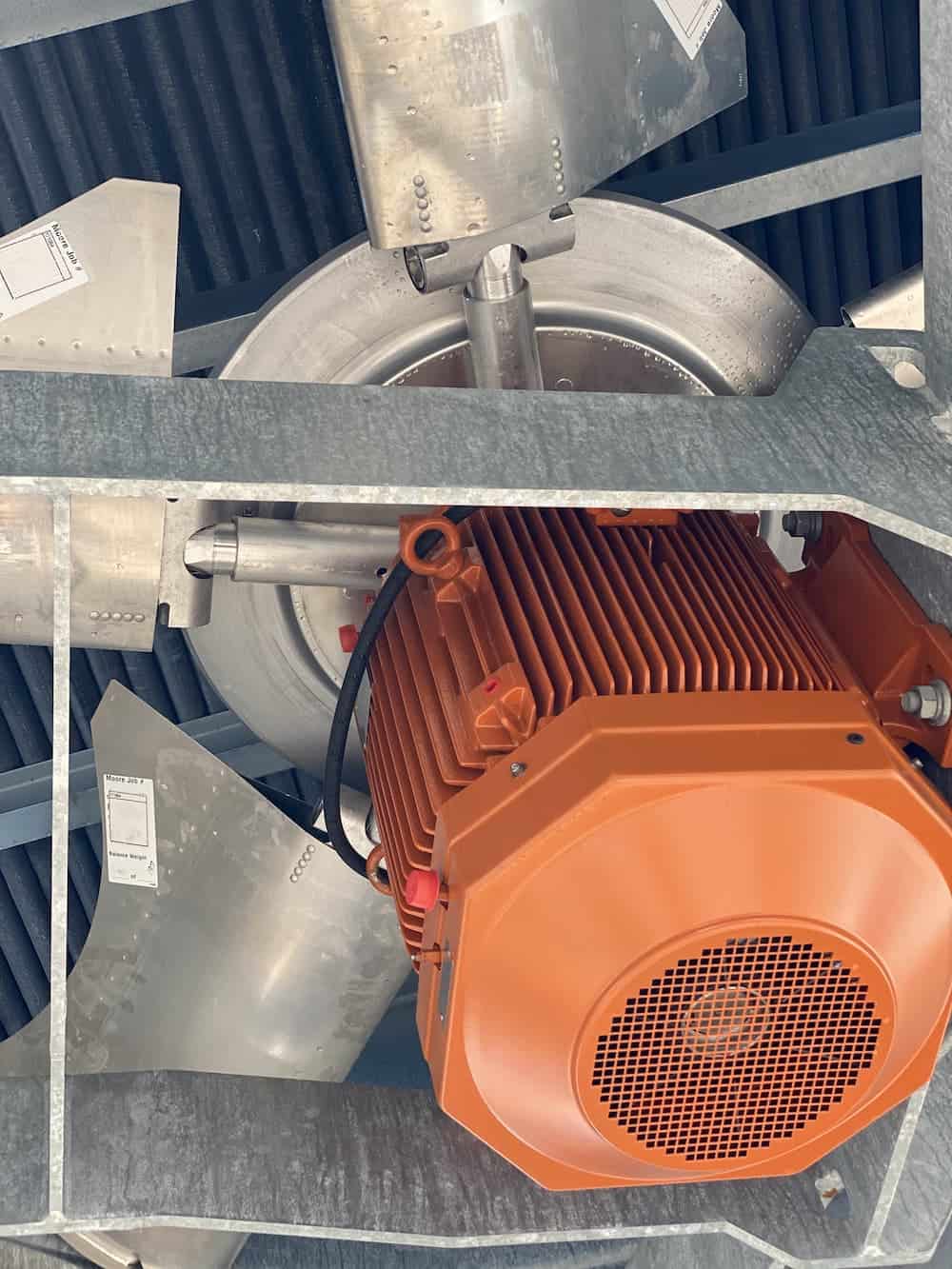

Electric motors

Electric motors are generally used as drivers, being selected to satisfy clients specific hazardous area requirements when required. Hydraulic motors may also be used, as well as low-speed direct-drive electric motors.

Airflow

Airflow can be controlled in one of the following ways:

• Variable-speed electric motors (variable frequency)

• Louvres (manual or automatic)

• Two-speed electric motors

• Automatic variable pitch fan

CNC MACHINING HEADERS

Spiro Gills has recently purchased a large Dugard CNC machine to for machining headers. This video shows a plug style header being manufactured at Spiro Gills factory in Stoke On Trent.

CONTACT FORM

If you would like more information on any of the services we offer or have any queries then please do not hesitate to contact us.

CONTACT INFO

Stafford

Spiro-Gills Thermal Products Ltd

St Albans Road

Stafford

ST16 3DR

England

St Albans Road

Stafford

ST16 3DR

England