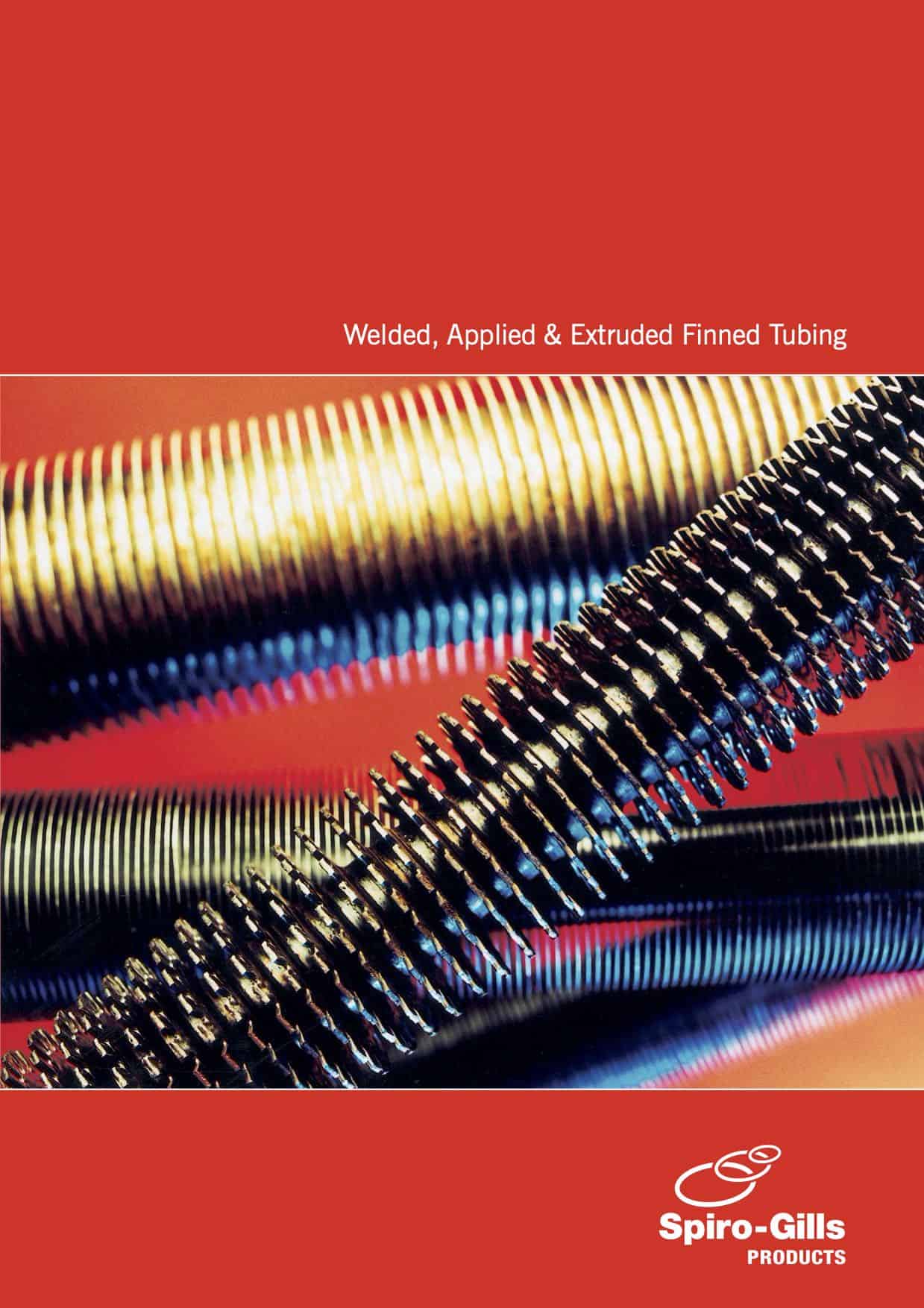

WELDED FINNED TUBE

HIGH FREQUENCY WELDED FINNED TUBES

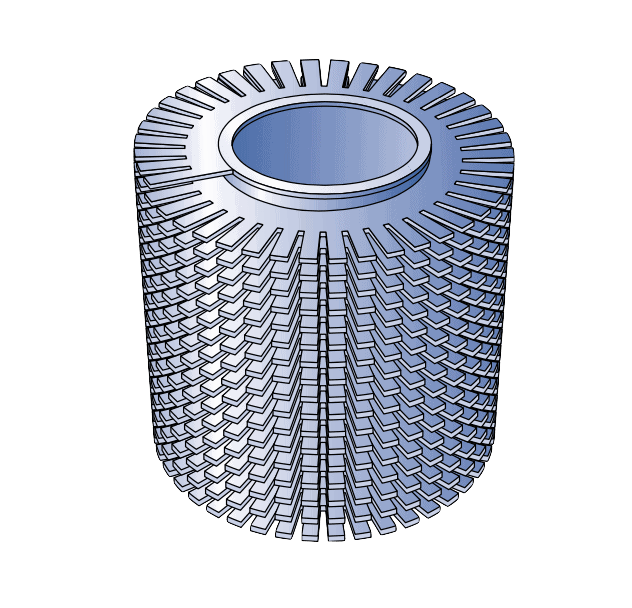

SERRATED FIN

Fin Height: 0.5–1.5” (12.7–38.1mm)

(higher on application)

Fin Thickness: 0.036–0.05” (0.9–1.27mm)

Fin Spacing: 1–7 per inch (39–276 per metre)

Tube Outside Diameter: 0.75–8” (19.05–219.1mm) Segment Width: 5/32, 5/16” (4.5, 8.0mm)

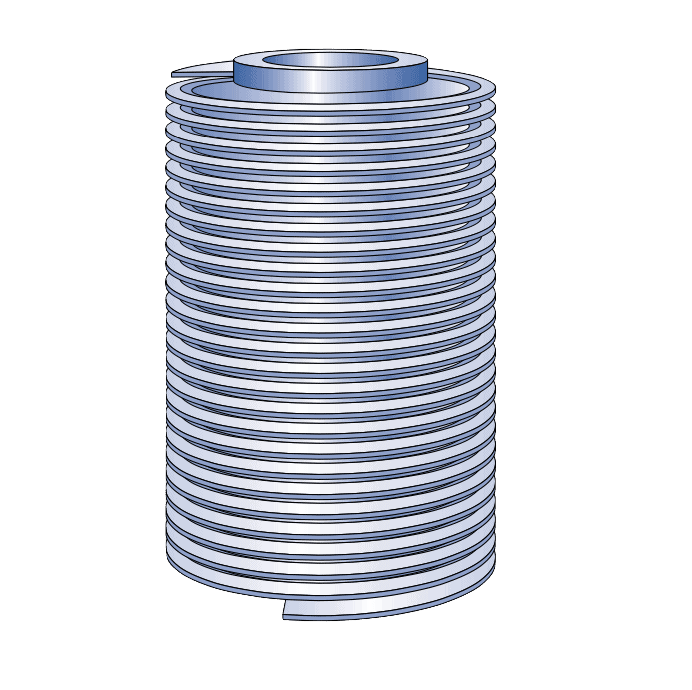

PLAIN FIN (SOLID FIN)

Fin Height: 0.25–1.0” (6.4–25.4mm)

(higher on application)

Fin Thickness: 0.036–0.098” (0.9–2.5mm)

Fin Spacing: 1–7 per inch (39–276 per metre)

Tube Outside Diameter: 0.75–8” (19.05–219.1mm)

Our finned tubes are helically wound using specialised high-frequency welding techniques and may have plain or serrated fin types. We have vast expertise and more than 50 years’ experience in this field. We originally produced finned tubes as Spiro-Gills Ltd in 1945 and have manufactured welded fin tubes since 1964 when the process was introduced.

Our equipment now operates in more than one hundred countries worldwide. Our pre-eminence in this kind of work enables us to offer customers:

Short lead times

An extensive range of material combinations for customised applications

Exceptional quality standards

THE ONLY WELDED FINNED TUBE MANUFACTURER IN THE UNITED KINGDOM

PRODUCT SPECIFICATION

Our machines are capable of handling tube /pipe sizes from 25mm o/d to 219mm o/d in carbon, alloy and stainless steels, as well as high nickel alloys. Fin sizes range from 6mm to 38mm high and from 1mm to 3mm thick in carbon steel, stainless steels (300 and 400 series) and high nickel alloys. Serrated fins are available in 4.5mm and 8mm segment widths.

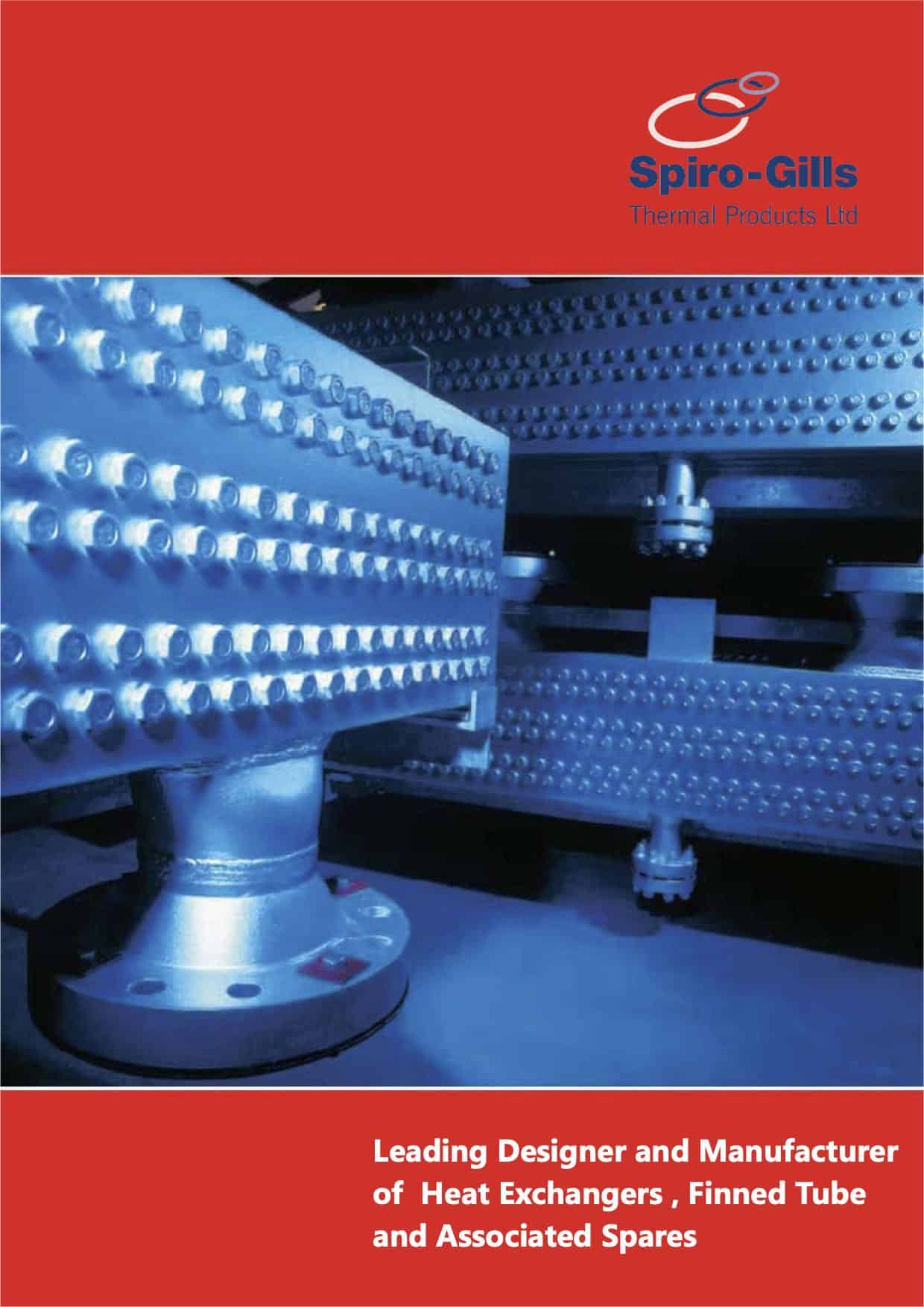

QUALITY

The Spiro-Gills name is a guarantee of high standards, and we implement quality assurance management to

BS EN–ISO9001:2000. We supply welded finned tubes in accordance with the international standard for dimensions, tolerances and test of HF resistance welded fins. We are a founder member of the international committee which produced this standard. We have also supported the setting up of an ASTM standard for HF-welded finned tubes. Spiro-Gills not only works within all international quality standards, in many cases it established those standards through its own quality leadership.

CERTIFICATION

Tube/pipe materials can be supplied with certificates according to BS EN–ISO10204.3.1A, B or C. Fin materials can be supplied with certification according to BS EN–ISO10204.2.2.

CORROSION PROTECTION

If required, the external surfaces of finned tubes can be treated with corrosion-resistant fluids.

WORLDWIDE AVAILABILITY

We despatch tubes throughout the world by road, rail, container or ship, and can offer a full export packing service on request.

AN EXCEPTIONAL SERVICE

In addition to manufacturing extended surface tubing, our sister company Spiro-Gills Ltd can incorporate it into the heat recovery system and supply it as a complete unit. As with our tube manufacturing processes, they work to recognised BS and ASME quality standards, employing highly-skilled certified welders and operating to stringent guidelines.

We believe the expertise and experience available to Spiro-Gills Products & Spiro-Gills Ltd in this field are unique, and are confident that major operators will find this a quite exceptional service.

EXPERTISE IN KEY PROCESSES

The processes involved in creating high frequency resistance welded finned tubing raise a number of interesting technical demands to which we bring highly specialist expertise and long experience of this kind of work.

For the benefit and interest of plant operators, we outline below some of the issues involved in:

- Resistance welding

- Weld quality

- Minimising pressure drop

High-frequency resistance welding usually employs a current of 450,000 Hz. With this technique, the fin is edge wound encircling the tube to give a continuous weld.

The forming of the fin around the tube and the heat of welding causes some upsetting or widening of the base of the fin, resulting in a contact area wider than the fin itself.

Here again, the function of the weld is to maintain the contact between the fin and the tube. Heat is thus transferred across the whole interface and not just through the weld itself. However, the quality of the HF weld is more important in maintaining negligible resistance to heat transfer between the fin and tube.

The use of high-frequency current results in very localised heating of the tube surface and the edge of the fin. This skin effect produces higher weld speeds and greater ease in welding difficult material combinations.

The HF process also allows much thicker fins to be welded. In fact, it is now possible to weld fins heavy enough to replace those previously available only with MIG, TIG and stud-welding processes, which are generally more expensive and require post-weld heat treating.

The HF process involves the use of heat and pressure to obtain coalescence of the fin and tube. An electric current is applied by contacts on the fin and tube, and the resistance in this circuit produces the heat necessary for welding.

Maximum resistance and therefore maximum heating occur at the interface between the fin and the tube. Pressure is applied by various forms of tooling to forge the fin and the tube together at the point of maximum heating.

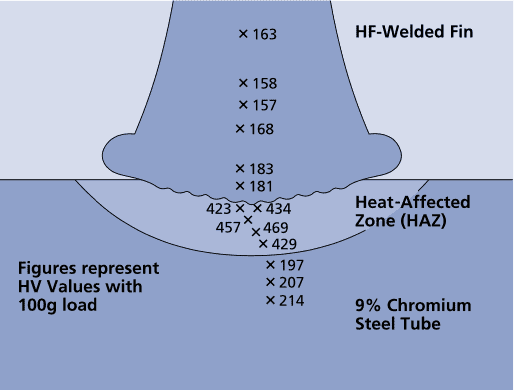

The resistance welding process produces a strong metallurgical bond between the fin and the tube while minimising the heat- affected zone (HAZ) in the tube.

The use of pressure to forge the fin and the tube together helps to minimise the heat input necessary to make the weld. In addition, the HF process allows the whole weld area to be continuously water-drenched which keeps the tube cool, except in the immediate area of the weld.

As a result, most common tube materials show little change in grain structure or physical properties when fins are welded to them.

The most notable exceptions to this are the 3% to 9% chromium steels which change from a ferritic to a martensitic microstructure in the heat-affected zone, with a significant increase in hardness.

The welding of fins to tubes is now easier and faster thanks to the use of the high-frequency resistance welding process.

However, operator skill and knowhow are still vital to produce consistently superior welds in the many different materials required by the power, chemical and petroleum industries.

In determining the quality of a weld by superficial examination, several elements should be noted.

In order to achieve fusion using a resistance welding process, the oxide layer on the tube and the fin must be displaced from the weld area, and this usually appears in the form of expulsion along both edges of the fin. It is difficult to achieve a satisfactory weld with no expulsion.

Corrugation at the base of the fin can also result in poor weld quality, and for this reason weld area tooling must be designed to minimise corrugation.

Where weld quality is of utmost importance, serrated types of fins should be considered, since many welding problems associated with forming plain fins around the tube are eliminated by using a segmented fin.

MINIMISING PRESSURE DROP

The manner in which the fin is formed around the tube can have a significant effect on the pressure drop of the fluid flowing through the fins.

To minimise pressure drop, the fin must be perpendicular to the tube, and corrugation at the base of the fin must be controlled.

Standards vary widely regarding the deviation of the fin from a perpendicular position. The more the fin is allowed to lean, the more the free-flow area is blocked and the pressure

drop increased.

Corrugation at the base of the fin causes similar effects, and must be minimised for best performance. In geometries where it is difficult to control corrugation, serrated fins should be considered, since this is not a problem with segmented fins.

The only UK Company to manufacture Welded and Applied Finned Tubes, Spiro-Gills has the ability to manufacture high-specification tube from 25mm to 219mm diameter for uses in Process /Engine Coolers, Boilers and Furnaces.

CONTACT FORM

CONTACT INFO

Stafford

St Albans Road

Stafford

ST16 3DR

England